Calcarea’s Tech Converts Cargo Ship CO2 into Ocean Salts

A US startup named Calcarea has made a significant breakthrough in sustainable shipping. The company has developed technology that captures carbon dioxide (CO2) emissions from cargo ships and converts them into stable ocean salts. This innovative process could store CO2 for up to 100,000 years. It presents a promising solution for reducing the maritime industry’s carbon footprint.

International shipping plays a vital role in global trade, facilitating about 80% of it. However, it also contributes approximately 3% of the world’s carbon emissions. The International Maritime Organization (IMO) has set stricter emission standards, aiming for net-zero emissions by 2050. As a result, the shipping industry is actively seeking effective ways to decarbonize. Unfortunately, the transition to low-emission fuels like methanol, hydrogen, and ammonia has been slow.

Calcarea, founded by Jess Adkins, a chemical oceanographer at Caltech, has developed a unique solution to this challenge. The startup’s technology involves installing specialized reactors on cargo ships. These reactors convert CO2 from the engines into ocean salts. This process mimics a natural reaction that occurs in the ocean.

“This is a reaction that the planet has been executing for billions of years,” Adkins explained. “If we can accelerate it, we could achieve a secure and lasting method for CO2 storage.”

The process begins by channeling exhaust gases from the ship into a reactor located within the vessel’s hull. The exhaust mixes vigorously with seawater and limestone, a rock mainly composed of calcium carbonate. The CO2 from the exhaust reacts with this mixture, producing saline water that sequesters CO2 as bicarbonate salts. In nature, this reaction could take over 10,000 years. However, Calcarea’s reactors can achieve it in about a minute by ensuring close contact between CO2 and limestone.

After the reaction, the saline water is discharged into the ocean. This process poses no danger to marine life. In fact, Calcarea’s approach has several advantages over traditional carbon capture technologies. Unlike scrubbers, which only capture sulfur emissions, Calcarea’s reactors also capture CO2.

Furthermore, Calcarea’s method accelerates a natural process without increasing ocean acidity. This avoids issues related to ocean acidification, which can harm marine ecosystems. Daniel Sigman, a professor at Princeton University, praises Calcarea’s approach, highlighting its benefits over other strategies.

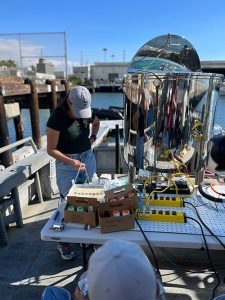

Calcarea has already developed two prototype reactors. One is located at the Port of Los Angeles, and another is at USC. The company has partnered with Lomar, an international shipping company, to test a full-scale prototype. These reactors will be customized for various ship sizes, including the massive Newcastlemax class.

Despite the promising technology, some technical issues remain. For instance, integrating reactors onto ships and managing limestone supply chains are challenges that need to be addressed. Currently, the cost of CO2 capture using this method is estimated at $100 per ton.

Adkins believes that Calcarea could significantly contribute to the shipping industry’s decarbonization as it transitions to greener fuels. He envisions a future where these reactors are installed on entire vessels designed to capture CO2 from the atmosphere. This would provide an alternative to underground storage.

“We believe that ships can compete with underground CO2 storage,” he stated. “These purpose-built vessels would collect CO2 and limestone at ports, travel out to sea, and operate our reaction—effectively serving as machines for the efficient and safe storage of carbon in the ocean as bicarbonate.”

As the world grapples with the urgent need to reduce greenhouse gas emissions, Calcarea’s innovative technology offers hope for the shipping industry. By harnessing the power of natural processes and accelerating them through engineering, the startup is paving the way for a more sustainable future, one cargo ship at a time.